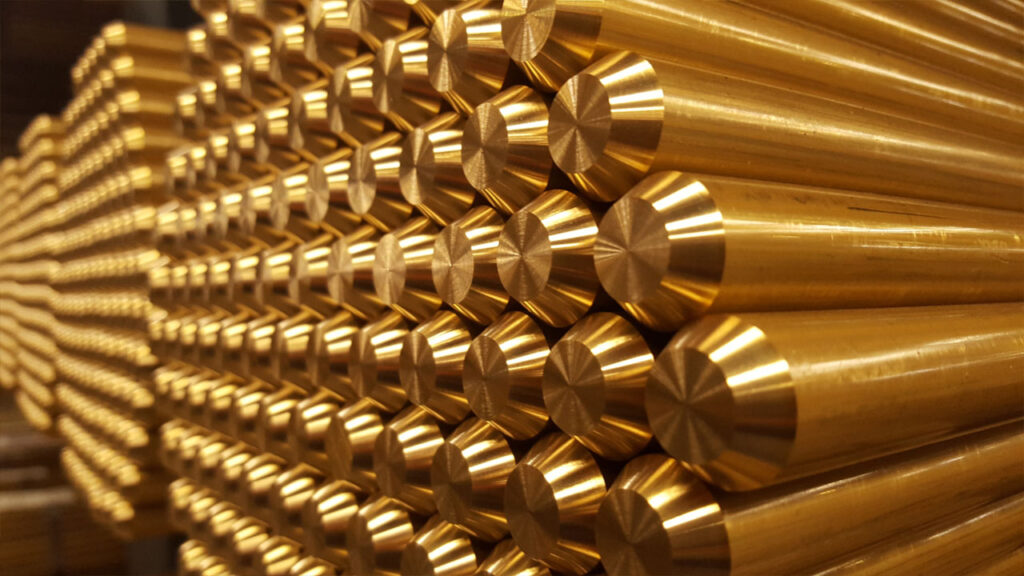

70/30 Brass Rods

Kanak Pipe Industries stands out as a prominent manufacturer of 70/30 Brass Rods in Mumbai, showcasing expertise in crafting this specific alloy. Defined by a composition of 70% copper and 30% zinc, 70/30 Brass Rods possess distinctive properties that render them versatile for a wide range of applications.

Key Characteristics and Uses of 70/30 Brass Rods:

- Corrosion Resistance: Renowned for its corrosion resistance, 70/30 Brass Rods are adept at withstanding environmental challenges, making them ideal for applications where exposure to moisture and corrosive elements is a concern.

- Machinability: Boasting excellent machinability, brass alloys, including 70/30 Brass, can be easily shaped, cut, and formed using various machining processes. This characteristic makes them well-suited for the manufacture of components with intricate designs.

- Electrical Conductivity: The inherent good electrical conductivity of brass is retained in the 70/30 Brass alloy, making it a preferred choice in applications requiring a conductive material, especially in the electrical and electronic industries.

- Aesthetics: With its signature golden-yellow color, 70/30 Brass maintains an aesthetic appeal. This characteristic makes it not only functional but also a sought-after material for decorative items, architectural elements, and musical instruments.

- Applications: 70/30 Brass Rods find extensive applications in diverse industries such as construction, plumbing, electronics, and automotive. Common uses include the production of valves, fittings, fasteners, electrical connectors, and various decorative items.

It’s crucial to acknowledge that the specific properties of 70/30 Brass may vary based on the exact composition and any additional alloying elements. For precise details regarding the properties and applications of 70/30 Brass Rods, it is advisable to refer to the specifications provided by the manufacturer or supplier.

Specifications

Product | Specification |

Bar | ASTM B36, B19, SAE J463, J461 |

Brazing Filler Metal | FEDERAL QQ-B-650 |

Cups, Cartridge Case | ASTM B129, MILITARY MIL-C-10375, |

Disk | ASTM B19 |

Plate | AMS 4507, 4505, ASTM B19, B36 |

Rod | SAE J463, J461 |

Sheet | AMS 4507, 5408, 4505, ASTM B19, B36, SAE J463, J461 |

Shim Stock, Laminated | MILITARY MIL-S-22499 |

Strip | AMS 4507, 4505, ASTM B36, B569, B19, B888, SAE J463, J461 |

Tube, Seamless | ASTM B135, FEDERAL WW-T-791, MILITARY MIL-T-20219, SAE J463, J461 |

Tube, Welded | ASTM B587, B587 |

Wire | ASTM B134, SAE J463, J461 |

Specifications | Designation |

ISO | CuZn30 |

European | CuZn30 |

BS | CZ 106 |

JIS | C 2600 |

Russian | L70 |

Chemical Composition:

Cu | Fe | Pb | Zn | |

Min/Max | 68.5 – 71.5 | 0.05 | 0.07 | Rem |

Nominals | 70.0000 | – | – | 30.0000 |

- Copper Tubes

- 90/10 Copper Nickel Tubes

- 70/30 Copper Nickel Tubes

- Admiralty Brass Tubes

- Aluminium Bronze Tubes

- Aluminium Bronze Tubes

- 95/5 CuNi, 80/20 CuNi, Cunifer

- Brasses