Kanak Pipe Industries Private Limited (KPIPL) has a totally integrated manufacturing facility. From casting to packing, all processes are carried out in- House.

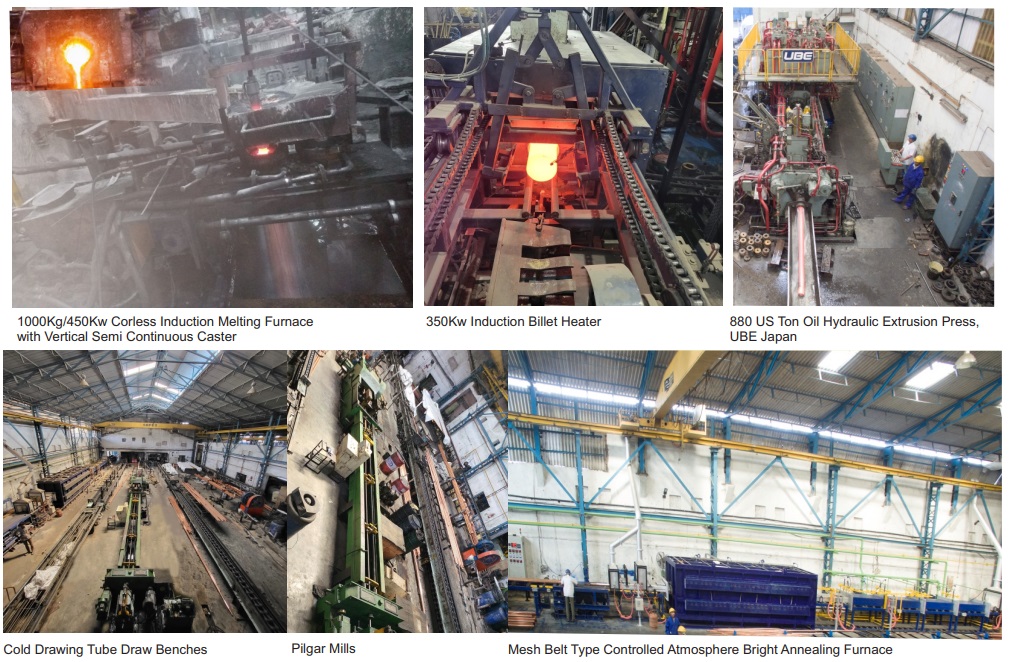

The Melting & Casting process carried out in Coreless Induction Melting Furnace VAP make 1000Kgs/450Kw and PILLAR make 500Kgs/250Kw capacity and Vertical Semi Continuous Caster.

We have 880 US Tons Horizontal Oil Hydraulic Extrusion Press of UBE Japan make. It is a PLC controlled and fully automatic operating cycle to produce quality extruded products of Copper and its alloys as Tubes, Rods & Sections. The Induction Billet Heating Furnace, coupled with extrusion press, has accurate temp. control of the billet with Radiation Pyrometer.

The finishing operation of tubes is carried out with Pilger Mills and a number of Precision Draw Benches of various pull capacities and sizes as per product requirements.

We are also equipped with a Mesh Belt Type Controlled Atmosphere Bright Annealing Furnace suitable for quality bright annealing of Copper and Copper alloys for intermediate & final annealing operation. The bright annealing furnace is coupled with an MVS make Nitrogen + Hydrogen Gas Generator producing gas at very low dew point (-60°C) and oxygen level 1ppm. A Precision control of Nitrogen & Hydrogen ratio is maintained to achieve best result of Bright Annealing.

We have recently added following Equipments to enhance the Quality of our Products: –

Vertical Semi Continuous Casting Machine:

The growing application of Billet Casting techniques, Vertical Semi Continuous Casting process furnishes the high quality of the billet surface, grain structure, long length, straightness and high recovery in casting, meaning production of high quality of billets or logs at competitive cost.

Pilger Mills:

Pilgering process ensures a large area reduction with respect to drawing without initiating surface cracks. It reduces a certain amount of eccentricity, which is not desired in precision tubes. Cold drawing gives only longitudinal stress whereas Pilgering imparts both longitudinal stress and transverse stress, resulting in a compact and globular grain structure.

Induction Billet Heater:

The advantage of Induction heating is less scale formation on the billet surface as well as environmental friendliness. Induction heating system suited for automation capability, quality assurance and high reliability. Our system also has the facility of combination of Gas heating at low temperature and further Induction heating to avoid scale formation on the billet surface, also reducing the temperature difference between the billet surface and the core.

Kanak Pipe Industries Private Limited (KPIPL) was established in 1991 and in 28 years, it has become India’s leading manufacturer of Copper and copper Alloy tubes, rods, sections, and Semis products.

©2024 Kanak Pipe Industries Limited | All Digital Services Powered By YUGASMI